The Importance of a Lean UX Process

The Importance of a Lean UX Process

Author : Ian Gabrielides

What is Lean UX and Where Does it Come From?

Firstly, Lean UX is short for Lean User eXperience. The roots of the lean UX process can be traced back to the adoption of Lean principles popularized by the likes of Toyota and the onset of Agile over the last decade or so.

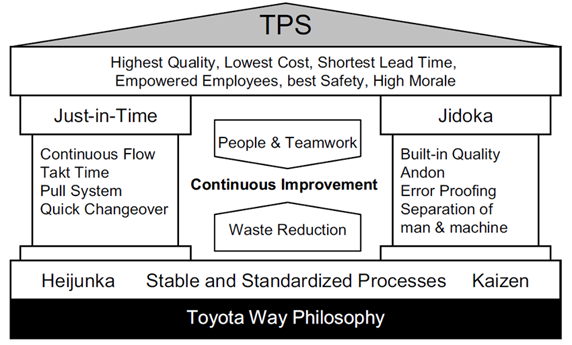

So, let’s start with those Lean origins before we focus on Lean UX. Whilst there are differing opinions, many cite the birth of Lean Manufacturing, (as we know it today) from the Toyota Production System (TPS). Lean Thinking came from the pioneers of the system Sakichi Toyoda, his sons Kiichiro and Eiji Toyoda as well as the influential manufacturing engineer Taiichi Ohno. This became the Toyota Way and visualised in two distinctive pillars, Just-In-time and Jidoka built on a foundation on sustaining and improvement methodologies. Just-In-time is a strategy that aligns raw-material orders from suppliers directly with production schedules. It minimises inventory and increases efficiency. The adoption of Lean methodology in manufacturing contributed to Toyota’s growth into one of the largest automotive companies in the world.

William Deming’s Influence on Lean UX Principles

The influence of William Edwards Deming, a US engineer can also be evidenced in Lean UX . Most organizations would say they were customer focused; however, their actions may be contradictory to this. Deming’s perspective goes beyond the statement that the organization is concerned with customers with a complete management philosophy and management system that directs resources to continually improve the value provided to customers. The organization needs an aim, a shared understanding of purpose in as far as delivering for their customer base (point 1 of Deming’s 14 points – Create constancy of purpose). This aim guides the organization and is adjusted over time as the marketplace and the organizations’ role (the value the organization aims to provide to customers) changes.

Deming's 14 points

- Create Constancy of Purpose

- Adopt the New Philosophy

- Stop Depending on Inspections

- Focus on Total Cost, Not Price Tag

- Improve Constantly and Forever

- Institute On The Job Training

- Institute Leadership

- Drive Out Fear

- Break Down Barriers

- Eliminate Unclear Slogans

- Eliminate Management by Objective

- Remove Barriers to Work Pride

- Implement Education and Self-Improvement

- Make Transformation Everyone’s Job

A Deming based organization uses evidence-based management practices to understand the value customers receive and the variation in the delivery of that value. This is central to the Lean UX process. A ‘Deming’ organization experiments by adopting the Plan-Do-Study-Act (PDSA) cycle by using in process measures to monitor and improve internal processes.

How Lean UX is Used by World Class Organizations

The evolution of Lean and Quality Improvement leads us to the Lean UX that we witness today and explains why there are several variants in the execution of Lean UX. Lean UX took principles that were originally designed for physical products and adapted them for software development. Whilst the likes of Toyota, Ford, Motorola had lean principles focused on driving out waste for the physical products they manufactured, users of Lean UX have been able to take these same principles but adapt them for software development. In many ways the word adapt undersells what product teams have been able to achieve with Lean UX. As they work in a virtual space not a physical one, the rate of improvement in the virtual world is so much quicker without the physical constraints. The likes of Siemens and Rolls Royce have been able to implement digital twin to build virtual processes before implementation. There are large up-front costs associated with these capabilities that don’t exist within Lean UX. As one leading Lean UX practitioner declared “you don’t have to follow the old measure twice, cut once idea. Instead, your Agile product teams (which are composed of experts from different departments) can come up with ideas, test them out quickly, and revise them based on customer responses and usability. You can measure once, cut once, measure once, cut once, measure once, cut once, forever!”

Jeff Gothelf, an organizational designer and UX lean design team leader drew on his experiences working for the The Ladders recruitment organization to publish the book Lean UX: Designing Great products with Agile Team (2013). Gothelf’s frustrations with the pace of change and the rigidity constraints when making improvements led him to develop the Lean UX concept. Reflecting on Lean UX and its successful adoption Gothelf declared than Lean UX is very much a mindset, in the same way Lean Enterprise is and Lean Manufacturing was before that. For that (Lean) mindset to be effective, it must be adopted by everyone within the organization. Lean UX focusses the digital design process, it’s a derivative of Lean manufacturing, a long-standing technique involving minimizing unnecessary steps in the manufacturing process that do not have any direct value for the customer. As aforementioned, this can be traced back to the Toyota Production System.

Fundamentally Lean UX and other forms of UX all have the same goal in mind; delivering a great user experience, the project delivery methodology is slightly different to what has come before. The core objective is to focus on obtaining feedback as early as possible so that it can be used to make quick decisions. The nature of Agile development is to work in rapid, iterative cycles and Lean UX mimics these cycles to ensure that data generated can be used in each iteration. Toyota built employee capability and empowered their team members to live by a similar mindset and behaviors.

Toyota believes that efficiency alone cannot guarantee success. What originally set Toyota apart from its contemporaries was that the company views employees not just as pairs of hands but as knowledge workers who accumulate chie—the wisdom of experience—on the company’s front lines. At Milliken we went through a parallel journey when Roger Milliken demanded the end to referencing employees as hands in favor of the term associates. This was very much a statement of intent, a very blatant top-down directive that the organization must tap into its greatest resource, its people, rather than a nuanced name change that has very little substance. Milliken, like Toyota invests heavily in people and organizational capabilities, and it garners ideas from everyone and everywhere: the shop floor, the office, the field. Toyota’s eagerness to allow their employees to experiment helps it clear the hurdles that stand in the way of achieving near-impossible goals. People test hypotheses and learn from the consequent successes and failures. By encouraging employees to experiment, Toyota moves out of its comfort zone and into uncharted territory.

Toyota believes that efficiency alone cannot guarantee success. What originally set Toyota apart from its contemporaries was that the company views employees not just as pairs of hands but as knowledge workers who accumulate chie—the wisdom of experience—on the company’s front lines. At Milliken we went through a parallel journey when Roger Milliken demanded the end to referencing employees as hands in favor of the term associates. This was very much a statement of intent, a very blatant top-down directive that the organization must tap into its greatest resource, its people, rather than a nuanced name change that has very little substance. Milliken, like Toyota invests heavily in people and organizational capabilities, and it garners ideas from everyone and everywhere: the shop floor, the office, the field. Toyota’s eagerness to allow their employees to experiment helps it clear the hurdles that stand in the way of achieving near-impossible goals. People test hypotheses and learn from the consequent successes and failures. By encouraging employees to experiment, Toyota moves out of its comfort zone and into uncharted territory.

Toyota has found that a practical way to achieve the impossible is to think deeply but take small steps—and never give up. It first breaks down a big goal into manageable challenges. Then it experiments to come up with new initiatives and processes for handling the more difficult components of each challenge. This pragmatic approach to innovation yields numerous learning opportunities. This approach is often referenced as Kaizen, which loosely translates to Chang (Kai) – Better (Zen). Lean UX focusses on detailed deliverables. You are looking to produce changes that improve the product in the here and now – essentially change the outcome for the better, Kaizen.

Lean UX focuses on waste like all other Lean Methodologies. Lean UX is a collaborative, user-centric approach to design that focuses on minimizing wasted time, money, and resources during the design cycle. Lean user experience design relies on a collaborative approach and rapid experimentation/prototyping, to get user feedback by exposing a minimum viable product (MVP – more about this later) to users as early as possible. Based on the lean agile methodology of making the design process incremental, Lean UX is a design strategy focused around minimizing wasted time and effort during the design process. It targets previous ways or working that are too slow and do not provide the customer with value in a timely manner. A huge issue in design when the lead-time to provide a service or product is greater than the window of opportunity with the customer or market. Imagine going through a drive through restaurant at breakfast time but only receiving your order at lunch time. You don’t want a breakfast and the restaurant has put all their efforts in putting the breakfast together. The restaurant has wasted time, resource and expense and you as the customer hasn’t enjoyed the experience you were expecting. All too often, UX designers will go full steam ahead with the product, and then either the requirements change, or the stakeholders just aren’t happy with the result. This makes all those months of hard work and research obsolete, and the entire team must go back to square one — costing the company time, money, and resources. The Lean UX approach asserts that a product’s initial prototype will always be wrong and need improvement, so it encourages the creation of a minimal viable product — a product with the essentials needed to conduct user testing. This approach is all about finding solutions to the problems and then improving those solutions based on user feedback.

The Use of Lean Design Teams in Manufacturing

A constant that has existed from the early implementation of lean within the Toyota Production System through to those using the Lean UX process today is the requirement realize improvements by deploying improvement teams, who draw on individual insights, ideas, and experiences. Toyota would by design, put people together that have differing views to create that collaborative spark. Team collaboration is fundamental to Lean UX. The product team tasked with making the offer better, (think Kaizen!) are a cross functional group who collaborate closely with one another to gather feedback early and often. They drive the design in short, iterative cycles to assess what works best for the business and the user. Lean UX shows you how to make this change—for the better (Kaizen!).

The formations of these product teams differ from organization to organization, especially as many of early Lean UX adopters have seen exponential growth and what worked during the start up or early days has had to evolve due to the size of the business. Ways of working must evolve from the Model Phase moving into the Scale Phase. Nicola Kilner, CEO of DECIEM the home of leading brands such as The Ordinary recently reflected on the Diary of a CEO Podcast with Steven Barlett.

“Chaos is fun in a start-up. It’s demotivating in a large organization”. The ordinary took eleven attempts to get the skincare brand where they wanted it to be, which Kilner reflected on, “A strategy can’t plan for that, we kept failing until we got it right. Our ethos was never plan, never have a strategy with Strategy is Overrated was one of the company slogans at the time” Deciem does indeed deploy strategy today due to the size of the organization but stays true to those Agile fundamentals that enabled them to be valued at $2.2 billion in 2017 (by Estée Lauder Companies) four years after starting in 2013. Kilner went on to say that Deciem never compromise on values that are so core to their purpose and their Mission Statement is Build Growth, power good.

The Deciem story is compelling for several reasons, many know the story because of Kilner and Truaxe’s personal tragedy and triumph, but others know their back story, a market disrupter that achieved excellence through Agile philosophies. Their product squads were able to work efficiently and diligently with their customers through the deployment of Agile methodology. Kilner credited her co-founder Brandon Truaxe identifying the need to be Agile when he stated Deciem needed to be the small rabbits running into the big holes that the elephants can’t get into. In other words, through the deployment of Agile. Deciem could take on the big market leaders by working differently, by being Lean, and adopting key Lean UX principles. One of the key drivers to this success was the family feel of the product squads (the product teams). Their ability to get products manufactured in house refined with the customer and re-launched within short intervals set them apart from their rivals.

What makes the squad model different is that each squad has the autonomy to release its work to the market (and autonomy is one of the traits of high-performing product teams). No executive stakeholder approval is necessary—no red tape. Instead, the squad develops new code, tests it until the team is satisfied, and then pushes it to the live product.

You can find another example of this model in Amazon’s “two-pizza” team structure. Amazon’s goal is to keep its internal teams lean and able to move quickly. The name comes from the idea that no team should be so big that two pizzas couldn’t feed everyone if they gathered for an evening meeting or work session. Amazon’s two-pizza model applies to all internal teams, not only product management. And these teams aren’t all as autonomous as Spotify’s Squads. Often, they still need to get the okay from a higher-up before they move forward with an idea.

But the general principles remain the same: Keep your teams as small as possible with the skills and resources they need to get work done. As any agile company knows, the goal isn’t to get the product right on the first try. Instead, the goal is to get something out there, learn what your users like about it, and then make the product better.

An Example Application of Lean UX Methodology

Once a team is formed, they follow their Lean UX methodology which are all fundamentally built on Demings PDSA cycle. Whether that is (i) Think-Make-Check, (ii) Hypothesize-Test-Analyze-Implement, or (iii) Build-Measure-Learn (other Lean UX methodologies exist). If we take the latter Build-Measure-Learn and looking these key steps in more detail.

1. Build

The step objective – to create a low-fidelity prototype that outlines the backbones and essentials of the product design.

Teams brainstorm possible areas for improvement based on customer feedback, customer research, competitor comparisons, and observing their product in use. They develop a problem statement, then decide which areas they want to improve. The process of finding these solutions is known as the assumption and hypothesis method. By looking at the problems, you should be able to come up with a problem statement which will then snowball into a set of assumptions — or, in other words, a statement that you believe to be true.

Assumptions are normally generated on a workshop basis. You get the team together and state the problem and then allow the team to brainstorm their ideas for solving the problem. In the process you generate answers to certain questions that form your assumptions.

Typical questions might include:

- Who are our users?

- What is the product used for?

- When is it used?

- What situations is it used in?

- What will be the most important functionality?

- What’s the biggest risk to product delivery?

There may be more than one answer to each question. That leaves us with a greater number of assumptions than it might be practical to handle. If this is the case, the team can prioritize their assumptions quickly following their generation. In general, you would prioritize your assumptions by the risk they represent (what are the consequences of this being badly wrong? The more severe the consequence the higher the priority) and the level of understanding of the issue at hand (the less you know, the higher the priority).

Remember - the framing of the question is so important. Henry Ford understood this right back when he formed his car company in 1903!

It means building a minimum viable product (MVP). This is a product that offers just enough features to attract early adopters. It needs to be adequate for testing (or measuring) the idea that we have defined. The Minimum Viable Product (MVP) is a core concept in Lean UX. The idea is to build the most basic version of the concept as possible, test it and if there are no valuable results to abandon it. The MVPs which show promise can then be incorporated into further design and development rounds without too much hassle. Here lies a link with traditional Toyota Lean thinking, with Jidoka. The Jidoka philosophy encourages operators to continually improve their working environment. They drive the basic solution through to the current best-known solution. Consider an operator stood on their production line inspecting product for defects. The first phase of improvement is the implementation of an Andon system, which allows the operator to leave their workstation to add value elsewhere in the organization and return to the line only when needed. The second phase of improvement is the move to automation, that doesn’t require the operator to attend the line at all. An MVP is the release of a new product or feature that is used to validate customer needs and demands prior to developing a fuller featured product. The product evolution in both cases (Jidoka and MVP) has many parallels with the customer and waste elimination central to both methodologies.

MVP is a product with enough features to attract early adopters

2. Measure

The step objective – to conduct a round of user testing based on your prototype, and use your hypothesis to test your assumptions.

Designers and developers build a new feature that will (hopefully) solve a problem and/or improve the product. After releasing our MVP, we proceed to use the technique(s) that we had settled on earlier to collect the data we need. We then go ahead to analyze the data we must find out what they are telling us.

3. Learn

The step objective – to analyze and deconstruct the feedback gathered before making the necessary improvements and taking the design to the next stage – what is the data telling you?

This is the point where we draw our conclusions based on the data available. Does it support or contradict our hypothesis? Do the results show that the idea we have is sustainable in the long run? Learning has to do with drawing valuable insights from the data at hand. It is about finding out if we should continue (by iterating), pivot, or start something new. Product teams test the new feature, using tools like UX surveys and A/B testing, to figure out whether their hypothesis was correct. If customers respond well to the new feature, it becomes part of the new design. If it doesn’t improve the customer experience, they return to the Build step and try something new.

If you have a lot of traffic to your website, A/B tests (or split tests) are a great way to validate your hypotheses scientifically and determine if the changes you made are working. Once you’ve got that result, you can go ahead and implement the changes confidently. A split test distributes website traffic between two different versions of a webpage—the original or baseline (version A) and a variation (version B)—which differ from each other in terms of design, content structure, page elements, etc. Observing how traffic groups respond to the version they're exposed to helps marketing and optimization teams determine which version offers the greatest conversion rate and opportunities for business growth.

The Organizational Benefits of Lean UX

If the steps of Lean UX are followed and the teams are disciplined in making decisions based on data rather than gut, feel they should enjoy a number of benefits that include but are not restricted to

- Elimination of waste in Design processes.

- Project timelines are optimized.

- Ability to share your insights with your team much earlier in the process.

- Focus On User’s Needs

- Build A Collaborative Environment

- Eliminates Heavy Deliverables

- Organizational alignment through the Minimum Viable Products (idea validation)

- Incorporate the voice of the customer throughout the project cycle

- Make your team more productive: combine Lean UX with Agile Scrum framework

- Create products that you know your customer will love

In addition to speeding up the design process, Lean UX allows your team to work smarter. This is driven by the way teams set about targeting goals. In Lean UX, everything is driven by customer value. This means that if a feature doesn't explicitly benefit the customer's experience, it won't be included in the initial plans. Lean UX is applicable to a number of organizations that are looking to adopt digitalization to reduce risk and increase value add for its employees. Whether it’s a laboratory looking to transfer data to its partners or a public Wi-Fi provider looking at ways to entice more users onto its product, the adoption of Lean UX maybe the key to the next phase of your lean journey. As the adoption of lean evolves depending on business and sector there are many things that traditional Lean Leaders can learn from the latest lean applications which includes Lean UX.

If you would like Lean UX coaching, education or hands-on Lean UX delivery support, get in contact with the Performance Solutions manufacturing consulting team to help us better understand if how we can partner with you on your journey.